The Unsung Hero: Why Industrial Brake Shoes Matter

2025.10.01

2025.10.01

Industry News

Industry News

In the world of heavy machinery and industrial operations, we often focus on the powerful engines, the intricate control systems, or the sheer scale of the equipment. But beneath the surface, a smaller, yet absolutely critical component ensures safety and efficiency: the Industrial Brake Shoe. These are not your average car brakes; they are robust, purpose-built devices designed to withstand immense forces and harsh conditions.

What Makes an Industrial Brake Shoe Unique?

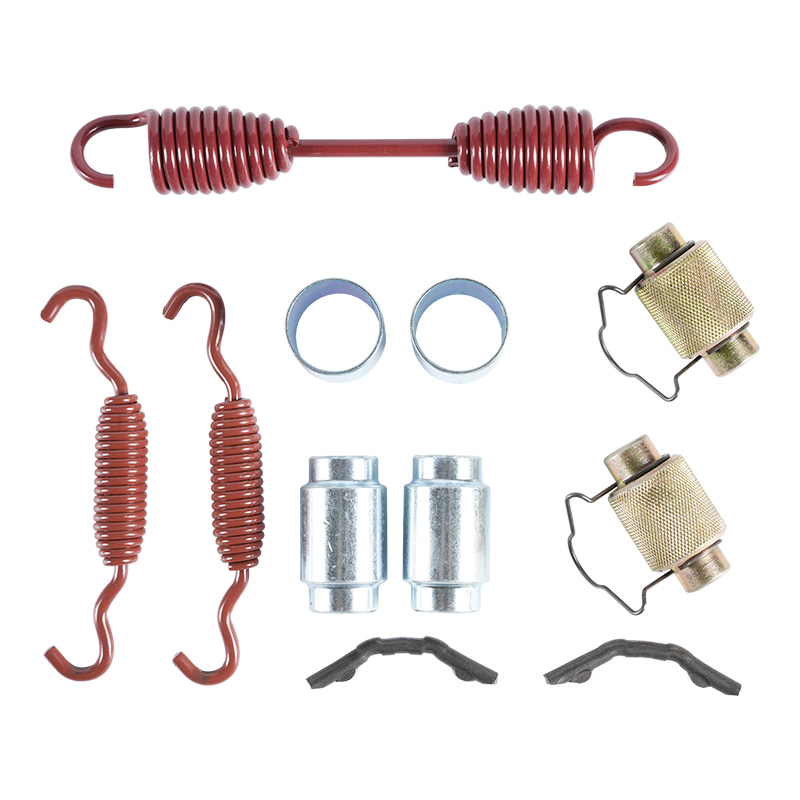

An industrial brake shoe is essentially a friction-based stopping mechanism. It's typically a curved metal component with a bonded or riveted friction lining. When activated, it presses against a rotating drum or wheel, creating the friction necessary to convert motion into heat and bring a machine to a controlled stop.

The key difference from automotive brake shoes lies in their construction and the materials used. Industrial applications demand materials that can handle extreme pressures and high, sustained temperatures without failing. The friction materials are the heart of the brake shoe's performance. They can include:

-

Sintered Materials: These are made from metal powders compressed at high temperatures, offering exceptional heat resistance and a high coefficient of friction for the most demanding tasks like in cranes and hoists.

-

Ceramic-Based Composites: Known for their durability and long life, these materials are ideal for high-performance scenarios where consistent, fade-resistant braking is a must.

-

Asbestos-Free Organic (NAO) Compounds: A modern, eco-friendly option suitable for a wide range of general industrial applications.

The choice of material isn't arbitrary; it's a precise engineering decision based on the specific needs of the machinery and its environment.

Critical Roles Across Industries

Industrial Brake Shoes are the silent guardians of safety in countless industries. Their function isn't just to stop motion but to hold and control it with precision. You'll find them in:

-

Cranes and Lifts: Providing the secure holding power that prevents catastrophic drops of heavy loads.

-

Conveyor Systems: Regulating the speed and ensuring accurate stopping points in manufacturing and mining operations.

-

Wind Turbines: Acting as a crucial safety mechanism to stop the massive blades during maintenance or in severe weather.

-

Elevators: Ensuring the cabin stops and holds firmly at each floor, a non-negotiable safety feature.

-

Oil and Gas Rigs: Controlling the descent and holding of heavy drilling equipment.

The Cost of Compromise

In industrial settings, every component is a link in a chain of safety and productivity. Opting for a low-quality Industrial Brake Shoes can have severe consequences. Inferior materials and poor construction can lead to premature wear, "brake fade" (a loss of braking power due to heat), and ultimately, equipment failure or, even worse, injury.

A high-quality industrial brake shoe is an investment in:

-

Reliability: Performing consistently under the most challenging conditions.

-

Longevity: Reducing downtime and maintenance costs through extended lifespan.

-

Safety: Providing the precise and dependable stopping power that is essential for protecting both equipment and personnel.

In the intricate world of industrial machinery, the Industrial Brake Shoe stands as a testament to the importance of foundational engineering. It’s a component that, while often unseen, is absolutely vital to the smooth and safe operation of our most critical industries.

Eng

Eng  中文简体

中文简体