Are Your Brake Shoes Failing? 5 Warning Signs You Can't Afford to Ignore

2026.01.14

2026.01.14

Industry News

Industry News

Understanding the Role of Brake Shoes in Drum Braking Systems

Brake shoes are a fundamental component of drum brake systems, typically found on the rear axles of many modern vehicles and as the primary stopping mechanism for older models and heavy-duty trucks. Unlike brake pads, which squeeze a flat disc, brake shoes are curved metal components with friction material bonded to their outer surface. When the driver applies the brake pedal, a wheel cylinder pushes the brake shoes outward against the inner surface of a rotating drum. This contact creates the friction necessary to convert kinetic energy into thermal energy, effectively slowing or stopping the vehicle.

The efficiency of a brake shoe depends heavily on its design and the quality of the friction lining. Most modern shoes are engineered to be "self-energizing." As the shoe makes contact with the rotating drum, the rotation pulls the shoe even more firmly against the surface, increasing braking force without requiring additional pedal pressure. Understanding this mechanical advantage is crucial for diagnosing issues such as "brake grab" or uneven wear between the primary and secondary shoes within the assembly.

Material Composition and Friction Characteristics

The performance of a brake shoe is largely dictated by the materials used in its friction lining. Manufacturers select these materials based on the vehicle's weight, expected heat load, and desired longevity. Below are the common types of friction materials found in the industry today:

- Organic (NAO): Made from fibers like glass, rubber, and carbon, these are quiet and soft on the drums but wear out faster under heavy use.

- Semi-Metallic: These contain metal fibers (steel or copper) to improve heat dissipation and durability, making them ideal for heavy-duty applications.

- Ceramic: Composed of ceramic fibers and non-ferrous fillers, these offer high temperature stability and very low noise, though they are often the most expensive option.

Heat Dissipation and Fade Resistance

One of the primary challenges for brake shoes is heat management. Because the shoes are contained within a drum, airflow is restricted compared to disc brakes. High-quality brake shoes use specialized resins to bind the friction material, ensuring that it does not glaze or "fade" when temperatures rise during prolonged braking, such as when descending a steep hill.

Comparison Between Brake Shoes and Brake Pads

While both components serve the same purpose, their application and physical demands differ significantly. The following table highlights the key differences between the two friction components to help clarify their specific roles in automotive engineering.

| Feature | Brake Shoe | Brake Pad |

| System Type | Drum Brakes | Disc Brakes |

| Action | Pushes Outward | Clamps Inward |

| Service Life | Longer (Rear Axle) | Shorter (Front Axle) |

| Heat Management | Enclosed / Slower Cooling | Exposed / Rapid Cooling |

Identifying Wear and Maintenance Requirements

Maintaining brake shoes is essential for vehicle safety, specifically for parking brake functionality and rear-end stability. Unlike disc brakes, which are easy to inspect visually, brake shoes require the removal of the brake drum for a full assessment. Technicians look for thinning of the friction material, uneven wear patterns, or signs of contamination from leaking wheel cylinders.

Common Symptoms of Failing Brake Shoes

- Scraping or Grinding Noises: This often indicates that the friction material has worn down to the metal backing plate, which can cause severe damage to the drum.

- Loose Parking Brake: Since the parking brake usually operates the rear brake shoes, a handle that pulls up further than usual suggests the shoes are worn or out of adjustment.

- Vibration or Pulsation: This may occur if the brake shoes are making uneven contact with a drum that has become "out-of-round" due to excessive heat.

Regular adjustment is a key part of brake shoe maintenance. While many systems feature "auto-adjusters" that activate when the vehicle is driven in reverse, these components can often seize due to rust or brake dust accumulation. Manually cleaning and lubricating the adjustment star wheel during a brake inspection ensures that the shoes maintain the correct clearance from the drum for immediate response.

Replacement Best Practices

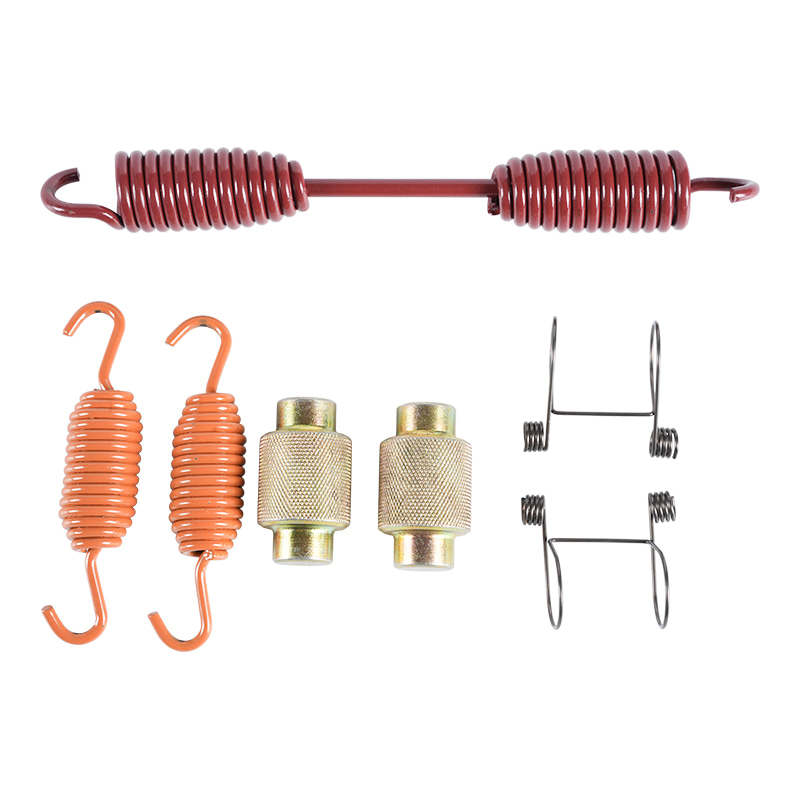

When it comes time to replace brake shoes, it is highly recommended to replace them in "axle sets" to ensure consistent braking across both wheels. Using a hardware kit that includes new return springs, hold-down pins, and adjusters is also a best practice, as these small components lose their tension over time due to heat cycles. Always ensure the internal surface of the drum is machined or replaced to provide a fresh "mating surface" for the new shoes, which prevents noise and extends the life of the new friction material.

Eng

Eng  中文简体

中文简体