Is Your Brake Shoe Assembly Failing? 5 Warning Signs You Can't Ignore

2026.01.06

2026.01.06

Industry News

Industry News

The Fundamental Architecture of the Brake Shoe Assembly

A brake shoe assembly is the core component of a drum braking system, primarily found on the rear axles of modern passenger vehicles and across all axles of heavy-duty trucks. Unlike disc brakes that pinch a rotor, the brake shoe assembly resides inside a hollow drum. When the brake pedal is depressed, hydraulic pressure forces the shoes outward, pressing the friction material against the inner surface of the rotating drum. This conversion of kinetic energy into thermal energy is what decelerates the vehicle. The assembly is a complex arrangement of high-tensile steel, heat-resistant friction linings, and a precise network of return springs and pins that ensure the shoes retract immediately once pressure is released.

Core Components and Their Functions

- Steel Table and Web: The structural backbone of the shoe, designed to withstand immense mechanical pressure without flexing.

- Friction Lining: A composite material (organic, semi-metallic, or ceramic) bonded or riveted to the steel table that creates the necessary grip against the drum.

- Return Springs: Heavy-duty springs that pull the shoes back to their "at-rest" position to prevent dragging and overheating.

- Wheel Cylinder: The hydraulic actuator that receives fluid from the master cylinder to push the shoes outward.

Comparison of Leading vs. Trailing Shoe Configurations

In most standard brake shoe assemblies, the shoes are categorized as "leading" or "trailing" based on their orientation relative to the direction of the drum's rotation. The leading shoe is "self-energizing," meaning the rotation of the drum actually pulls the shoe tighter into the friction surface, increasing braking force naturally. The trailing shoe is pushed away by the drum's rotation, providing a more stable and predictable braking feel. Understanding this balance is critical for technicians when replacing components, as installing shoes in the wrong orientation can lead to uneven wear or significantly reduced stopping power.

| Feature | Leading Shoe | Trailing Shoe |

| Force Direction | Assists rotation (Self-energizing) | Opposes rotation |

| Wear Rate | Typically faster due to higher friction | Slower and more uniform |

| Heat Generation | Higher heat concentration | Lower heat concentration |

Critical Maintenance and the Self-Adjuster Mechanism

One of the most vital aspects of the brake shoe assembly is the self-adjuster mechanism, often referred to as the star wheel. As the friction material wears down over thousands of miles, the gap between the shoe and the drum increases, which would normally result in a "low" or "spongy" brake pedal. The self-adjuster automatically expands the assembly to maintain a consistent clearance. Maintenance involves ensuring these moving parts are cleaned and lubricated with high-temperature brake grease. Neglecting this often leads to the adjuster seizing, causing the rear brakes to become non-functional and shifting the entire braking load to the front discs, which accelerates front-end wear and increases stopping distances.

Signs of Assembly Failure

- Scraping or Grinding: Indicates that the friction material is completely depleted and the metal table is contacting the drum.

- Soft Brake Pedal: Often a sign of a leaking wheel cylinder within the assembly or air in the hydraulic lines.

- Parking Brake Failure: Since the parking brake usually operates the brake shoe assembly via a cable, inability to hold on an incline suggests worn shoes or a seized adjuster.

Best Practices for Brake Shoe Replacement

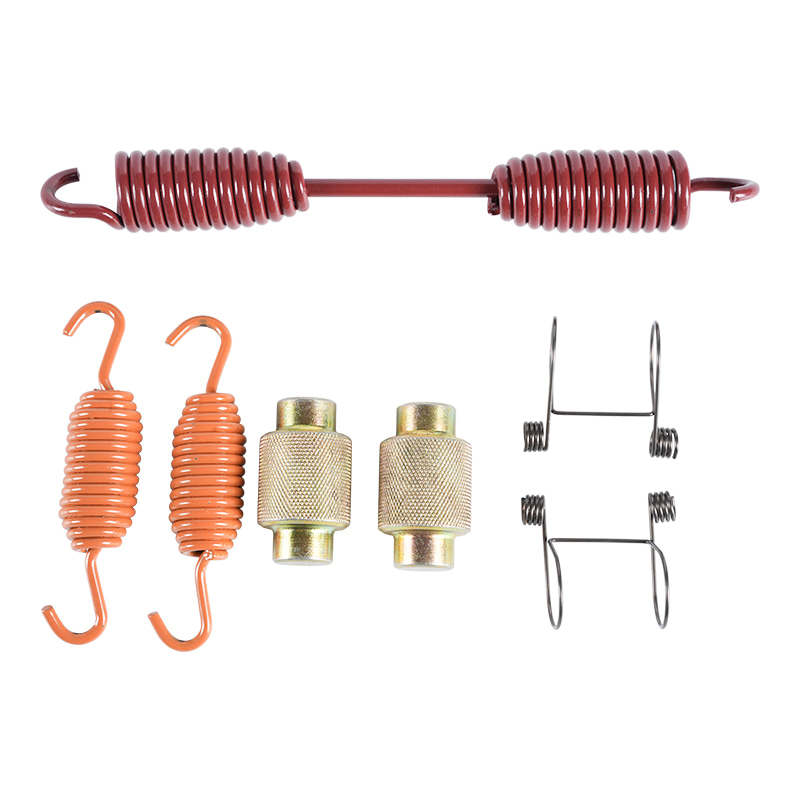

When performing a replacement of the brake shoe assembly, it is a professional standard to replace components in pairs across the axle to maintain balanced braking. It is also highly recommended to install a new "combi-kit" or hardware kit, which includes fresh return springs, hold-down pins, and clips. Over time, the constant heating and cooling cycles cause the original springs to lose their tension, which can lead to brake drag even if the shoes themselves are new. Finally, always resurface or replace the brake drums to ensure a smooth mating surface, which facilitates the proper "bedding-in" process of the new friction linings.

Eng

Eng  中文简体

中文简体