Precision Restoration: Diving Deep into the Brake Assembly Repair Kit

2025.10.22

2025.10.22

Industry News

Industry News

The efficiency and safety of any vehicle rely heavily on its braking system. When that system begins to show signs of wear—such as leaks, sticking components, or sluggish performance—the integrity of the entire brake assembly is compromised. While full replacement is an option, a far more targeted and economical solution is the brake assembly repair kit. This specialized product is the cornerstone of effective brake maintenance, allowing mechanics and DIYers to restore critical components to their original operating condition. [Photo close-up of new rubber seals and boots from a repair kit]

Anatomy of a Restoration: What the Kit Fixes

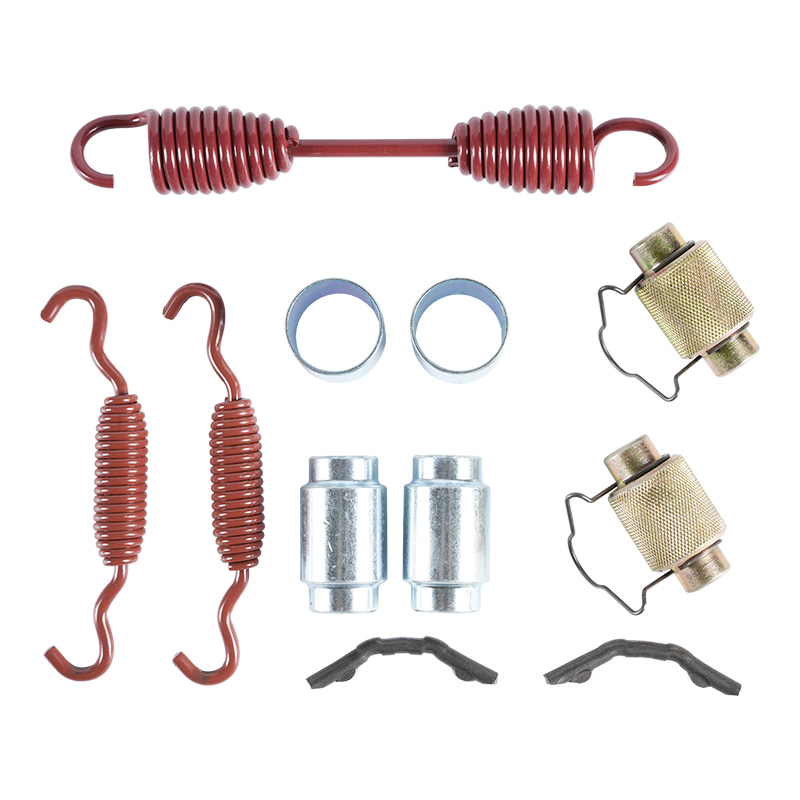

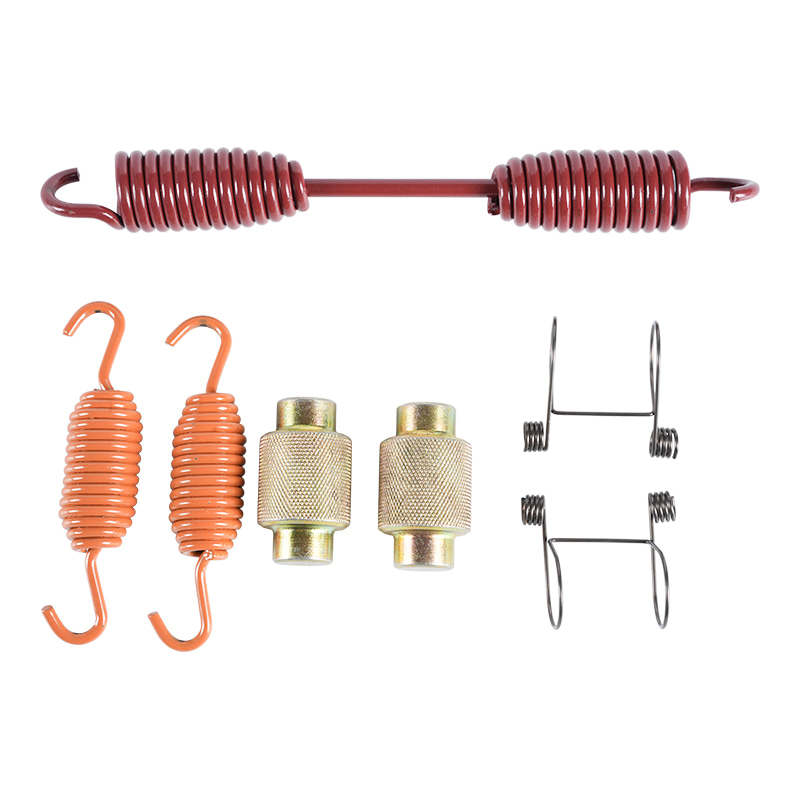

The primary wear parts in a brake system are the non-metallic seals, boots, and springs, which are constantly exposed to heat, aggressive brake fluid, and road contaminants. The brake assembly repair kit targets these exact components, offering a complete set for the full rehabilitation of a single brake unit.

For a typical brake caliper, the kit focuses on the piston and the bore:

-

High-Temperature Seals: The most crucial components, these are the square-cut or O-ring seals that sit in the caliper bore. They not only prevent hydraulic fluid from leaking but also provide the small degree of piston retraction necessary after the brake pedal is released. The quality of these seals, often made of EPDM or similar chemical-resistant rubber, is paramount.

-

Dust Boots: These accordion-style rubber components prevent moisture, salt, and dirt from reaching the highly polished piston and cylinder bore. A tear in a dust boot is a common precursor to caliper seizure.

-

Slide Pin Boots and Hardware: For floating calipers, the kit may also include new boots for the guide pins, ensuring they can move freely, which is vital for even pad wear.

For drum brake wheel cylinders, the brake assembly repair kit addresses the sealing components:

-

Piston Cups: These are the rubber seals on the ends of the pistons that ensure the hydraulic pressure is contained within the cylinder and applied to the brake shoes.

-

Springs: Small return springs may be included to ensure the pistons retract properly.

The focused nature of the brake assembly repair kit makes the repair process surgical. Instead of discarding perfectly good metal components, you are merely replacing the perishables.

Quality and Selection: Choosing the Right Repair Kit

Not all repair kits are created equal. Since the performance of the seals and boots dictates the safety of the entire braking system, selecting a high-quality brake assembly repair kit is crucial. Look for kits that:

-

Are Vehicle-Specific: The dimensions of the seals and boots must match the piston and bore exactly. A kit designated for a specific Year, Make, and Model ensures compatibility.

-

Use Premium Materials: Seals should be made from materials that are compatible with DOT 3, DOT 4, or DOT 5.1 brake fluids and can withstand extreme temperatures without swelling or degrading.

-

Include Necessary Lubricants: The kit should provide a small packet of specialized brake grease for the slide pins or piston (where applicable) to ensure smooth, noise-free operation.

The brake assembly repair kit is more than just a collection of rubber parts; it is a meticulously assembled solution that delivers the precision components needed to safely and effectively restore the integrity of your vehicle's most critical safety feature. It embodies the principle that often, a targeted repair is better—and certainly more economical—than a complete replacement.

Eng

Eng  中文简体

中文简体