The Essential Guide to Heavy-Duty Brake Shoes: Performance, Safety, and Maintenance

2026.02.03

2026.02.03

Industry News

Industry News

Understanding the Engineering of Heavy-Duty Brake Shoes

In the world of commercial transportation and industrial machinery, the braking system is the most critical safety component. Heavy-duty brake shoes are specifically engineered to handle the immense kinetic energy generated by vehicles weighing several tons. Unlike standard automotive brakes, these components utilize high-density friction materials bonded or riveted to a reinforced steel backing. This construction ensures that under extreme pressure and high-temperature conditions, the shoe maintains its structural integrity without warping or cracking, providing consistent stopping power for trucks, trailers, and buses.

The performance of heavy-duty braking components relies heavily on the "lining" or friction material. Modern manufacturers often use non-asbestos organic (NAO) or semi-metallic compounds that are designed to dissipate heat rapidly. Effective heat management is vital because excessive thermal buildup can lead to brake fade, a dangerous condition where the friction coefficient drops significantly. By choosing premium heavy-duty brake linings, operators ensure a more reliable braking response even during long descents or frequent stop-and-go cycles in urban environments.

Key Technical Specifications and Comparisons

Selecting the right equipment requires an understanding of the specific demands of your application. Heavy-duty friction products are categorized by their Gross Axle Weight Rating (GAWR) and their ability to withstand "shear stress." A high-quality brake shoe must offer a perfect balance between longevity and rotor/drum protection. If the shoe material is too hard, it may cause premature wear on the drums; if it is too soft, the shoes will require frequent replacement, increasing the total cost of ownership.

| Feature | Standard Duty | Heavy-Duty Application |

| Thermal Resistance | Up to 350°C | Up to 650°C+ |

| Material Base | Organic/Ceramic | Semi-Metallic/Sintered Iron |

| Durability | Moderate | High Fatigue Resistance |

Signs of Wear in Heavy-Duty Braking Systems

Proactive maintenance is the only way to prevent catastrophic failure in heavy-duty vehicles. Technicians should regularly inspect the thickness of the brake linings to ensure they have not worn down to the rivets or the metal table. Uneven wear patterns on the heavy-duty brake shoes often indicate underlying issues such as seized S-cams, worn bushings, or improper slack adjuster calibration. Addressing these issues early can save thousands in emergency repairs and prevent vehicle downtime.

Common Indicators for Replacement

- Audible squealing or grinding noises during deceleration.

- Visible heat cracks on the surface of the friction material.

- Reduced air pressure efficiency or longer stopping distances.

- Vibrations felt through the chassis when the brakes are applied.

Best Practices for Installation and Longevity

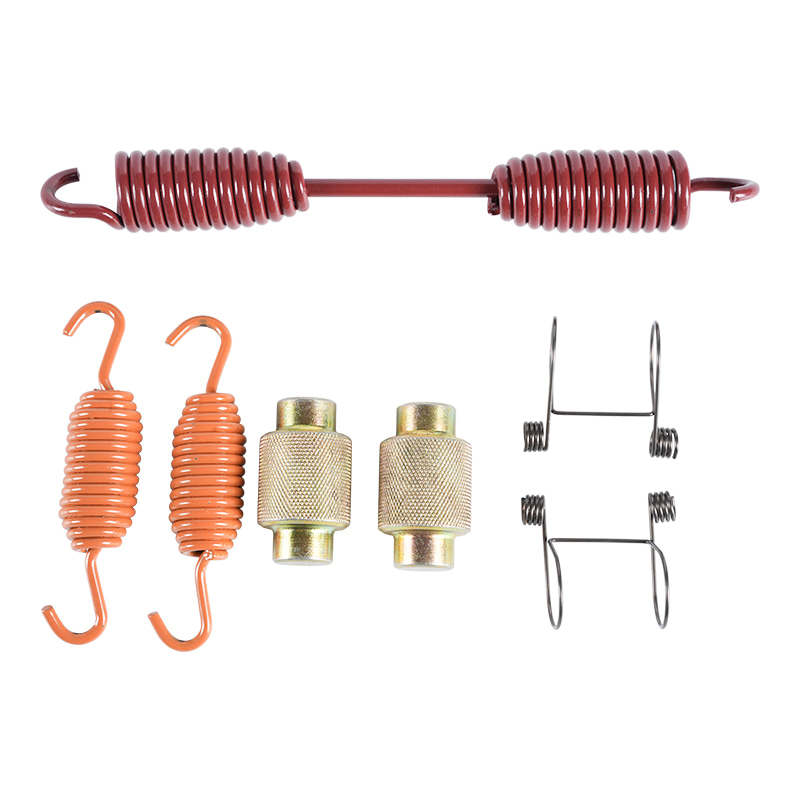

Proper installation of heavy-duty brake shoes is just as important as the quality of the part itself. When replacing shoes, it is highly recommended to replace the hardware kits, including the return springs and rollers. Weak springs can prevent the shoe from fully retracting, causing constant friction and "dragging," which destroys the new lining through glazing. Glazing occurs when the resin in the friction material melts and creates a smooth, glassy surface, drastically reducing the stopping capability.

Furthermore, ensuring the brake drum is within the discard diameter and free of deep scoring is essential for the new heavy-duty brake shoes to seat correctly. A proper "burnishing" or "bedding-in" procedure should follow every installation. This process involves a series of controlled stops that transfer a thin layer of friction material onto the drum surface, optimizing the contact patch and ensuring the system operates at peak efficiency from the first mile.

Eng

Eng  中文简体

中文简体